Engineered to be more efficient, more economical, more eco-friendly.

From tough conditions in the mining industry to mission critical operations in hospitals, our boilers are designed and built to perform for a lifetime. Our business is based on internationally competitive technology, price and delivery. We provide the full spectrum of products and services to our customers in South Africa and many export markets.

Package Boilers

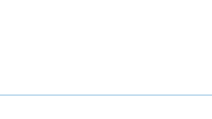

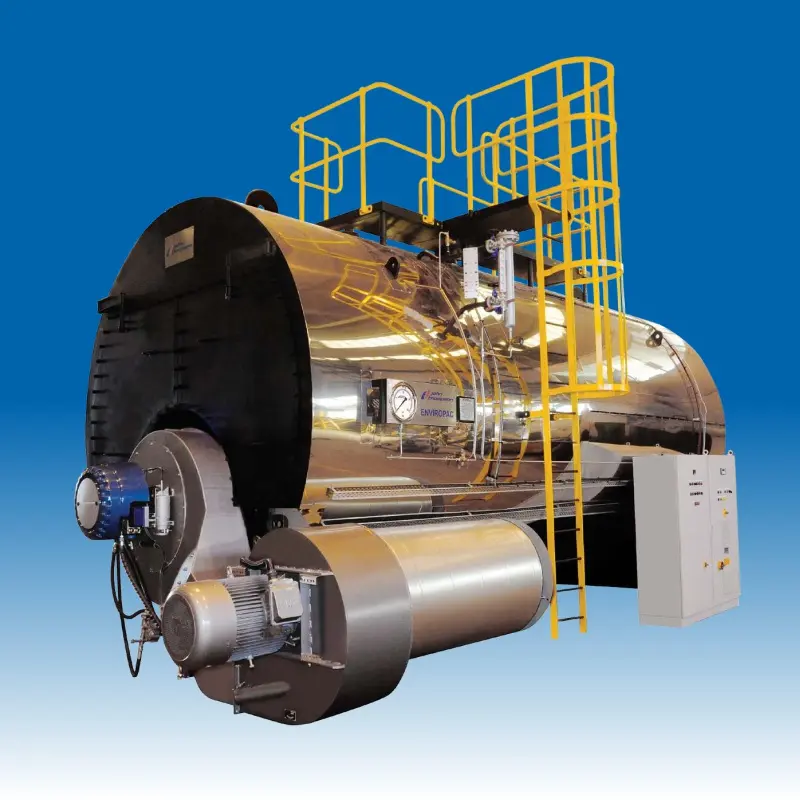

During the past 60 years we have supplied over 4 000 firetube boilers to customers in many industries in Africa, Europe, South-East Asia, the Middle East, South America and Australia.

All of our boilers now incorporate spiral-tube technology, developed in our test centre. This enhances thermal efficiency and reduces fuel consumption and CO2 emissions.

The boilers are designed and manufactured in compliance with the latest international standard, EN12953.

An Approved Inspection Authority inspects and certifies each piece of equipment before dispatch.

Thompson Europac Coal-Fired

Thompson Enviropac Oil/Gas-Fired

Thompson Redipac Oil/Gas-Fired

Thompson Simpac Wood-Fired

Thompson Toripac Biomass-Fired

Waste-Heat Boilers

Micropac and Lamtec Control Systems

Triumph Chaingrate Stoker

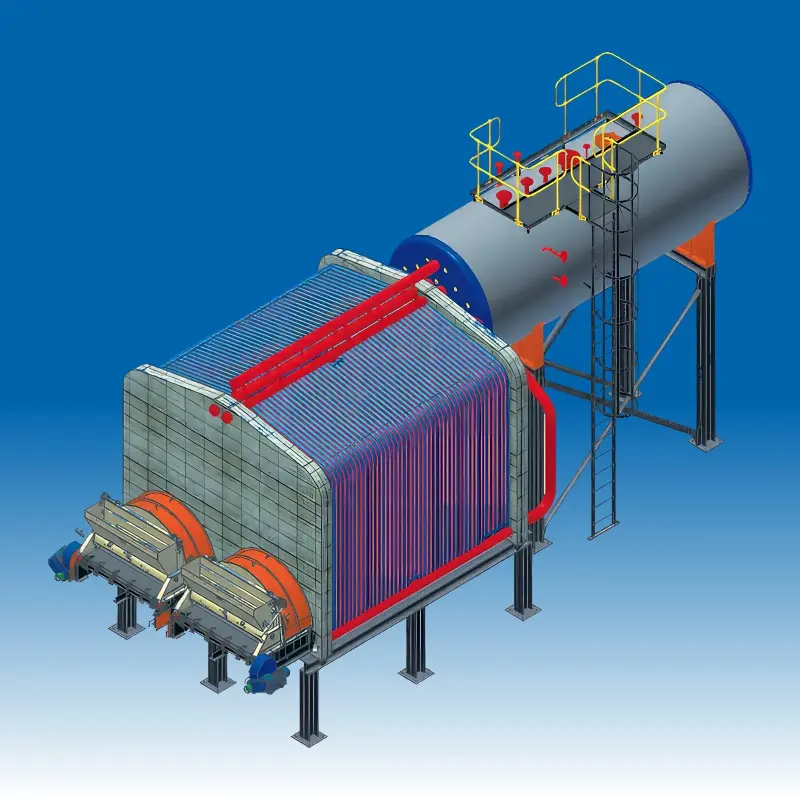

Industrial Watertube Boilers

Throughout sub-Saharan Africa, customers in major industries such as mining and hospitals turn to John Thompson for new boilers and combustion equipment.

They also entrust the repair and maintenance of such key equipment to our expertise.

Our service further includes capacity and efficiency improvements to older boilers, supply of original equipment manufacturer (OEM) spares, reliability studies and metallurgical services.

Industries served: mining, hospitals, sugar, food and beverage, chemical, petrochemical, steel, metallurgical, pulp and paper, textiles and many others.

Typical Bagasse-Fired Watertube Boiler

Typical Eckrohrkessel Cornertube Boiler

Utility Boilers & Auxiliaries

John Thompson specialises in the construction and maintenance of power and utility boilers. These boilers include supercritical boilers with pressures up to 276 bar at superheated steam temperatures up to 569 °C. We are experts in the welding of alloys for high temperature and pressure applications typically used in boiler construction and boiler maintenance services.

Our services include the construction, maintenance and refurbishment of various boiler auxiliaries such as coal mills, pulverised fuel burners and piping, ducting and flue gas cleaning equipment.

We supply boiler piping and tubing, as well as manufacture specialised boiler components. Quality is ensured through the application of the Pressure Equipment Regulations, SANS 347, ISO 9001, ISO 3834, client specifications and requirements, and our own standards.

Our execution practices optimise productivity and minimise downtime, while adhering to strict quality and safety standards.

Our services cover more than 30 utility boilers, boilers in the paper industry and nuclear power plants.

Boilers

High Pressure Piping

Coal Mills & Pulverised Fuel Burners

Nuclear Industry

Safety and quality are paramount in the nuclear industry. John Thompson strictly adheres to the South African National Nuclear Regulator’s requirements on quality and safety management as per RD0024, thus ensuring the highest quality and safety standards.

John Thompson has been offering these services to the nuclear power generation industry since 2020, after developing a Nuclear Safety Culture within the organisation.