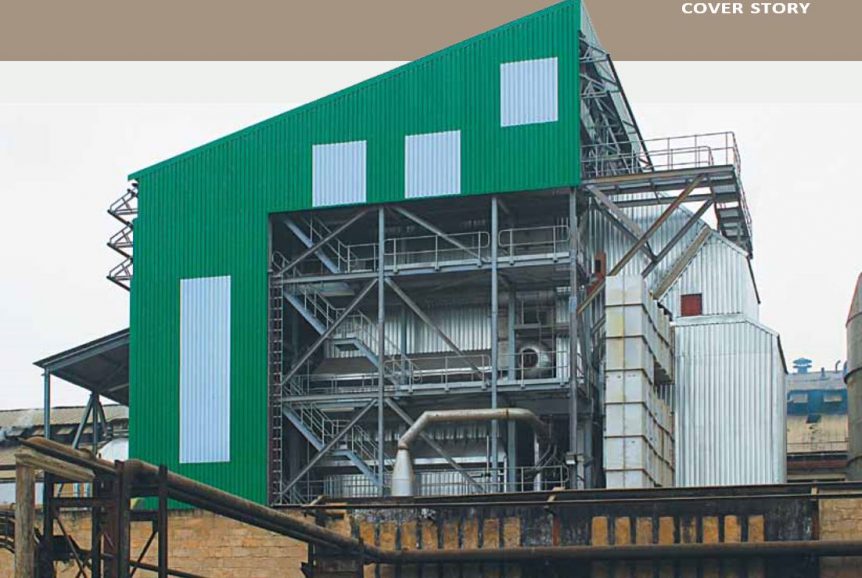

John Thompson, the Cape Town based designer and manufacturer of industrial boilers and ancillary equipment, has successfully carried out the performance tests on an 80 t/h bagasse-fired watertube boiler and pre-boiler plant that they supplied for the sugar mill of Compagnie Sucriére de Kwilu Ngongo (CSKN) in the Democratic Republic of Congo (DRC)

CSKN, in which the DRC Government has a 40% share, was established in 1925 and is currently the only operational sugar mill in the DRC. It comprises cane sugar plantations, a sugar mill and a distillery, which is the home of the Congo’s famous Kwilu Rum. CSKN, located near Kwilu in Bas-Congo, is part of the Belgium-based Finasucre group, which has various other sugar related interests in Europe, Australia and the USA.

John Thompson’s contract was secured against fierce international competition from India and France and was the first won by them for a watertube boiler plant in the DRC.

The new boiler, which has replaced three old 25t/h boilers as part of a planned staged capacity increase at the mill, operates in tandem with an existing 70t/h boiler.

Boiler design

The boiler is designed to operate at a pressure of 31 bar with a steam temperature of 385°C. It is John Thompson’s standard girth supported design in which the combustion chamber is suspended from a support plane just below mud drum level from where it is free to expand vertically upwards and downwards. The mud drum is supported directly off the boiler steelwork and the upper combustion chamber thus expands at the same rate as the generating bank.

The design incorporates a tall fully water-cooled combustion chamber, single-stage pendant superheater, single-pass generating bank and heat recovery equipment comprising a two-stage parallel-flow airheater to meet the required initial thermal efficiency on GCV of 64%. Space is provided below the airheater for the future retrofit of an economiser in order to increase the GCV thermal efficiency to 70%.

The boiler is fitted with John Thompson’s well proven three-drum bagasse feeders, pneumatic spreaders and stationary water-cooled pin-hole grate.

The draught plant incorporates single FD, SA and ID fans. The ID fan has an AC variable-speed drive together with discharge isolation damper, while the FD and SA fans are both fixed-speed damper controlled units.

A wet gas scrubber of the irrigated sieve plate design is installed between the back-end heat recovery equipment and the ID fan in order to limit particulate emissions to below 250mg/nm3 in accordance with project requirements. Flue gases exit through a self-supporting chimney stack. Boiler turn-down In order to meet the distillery operating requirements during the off-crop period, the boiler is capable of steaming at a load of 20t/h at 31 bar continuously when firing bagasse, as specified. The final steam temperature at this load, measured at the superheater outlet manifold, is 365°C (±15°C).

Project challenges

Of the many challenges faced on this project, one of the most onerous involved the logistics associated with importing equipment into the DRC. The nearest point of entry to the mill is the port of Matadi, on the Congo river, through which all equipment had to pass. Clearing of the consignments took place at the custom’s facility on the factory site.

In addition, with the DRC being a French speaking country, communication was not always straight forward and some interesting interpretations were encountered as the project progressed!

The tropical weather posed yet another challenge. The client was obliged to complete the boiler civil works before end-October the start of the rainy season, which carried on until April the following year (their traditional off-crop period). Being only 5 months from contract commencement, finalisation of the civil layouts and design was therefore on the critical path and had to be carefully managed.

In order to mitigate some of the logistics risks and to minimise costs, CSKN undertook some of the more bulky fabrication works themselves in their well-equipped workshops on site. They were also responsible for supplying some local services, including refurbishing a vacant building to accommodate John Thompson’s site staff.

John Thompson provided the supervision and technical advisory services to oversee the construction and quality aspects associated with the site works.Upon completion of the installation, they commissioned the boiler plant and carried out the performance tests.

John Thompson is a division of Actom the largest manufacturer, solution provider, repairer and distributor of electro-mechanical equipment in Africa. They have over 80 years of service to South Africa’s industries.

John Thompson, Russell Warren

Tel: (031) 408-9700

Email: russellw@johnthompson.co.za