Innovative product made possible by advanced modelling techniques

Environmental conservation and the current financial climate have a great impact on the industrial boiler market. Most industries are considering renewable energy resources such as biomass combustion plants which are CO2 neutral and sustainable in an agricultural system. Equipment upgrades are also attractive due to the reduced capital outlay in comparison to new equipment.

As an industrial boiler supplier, some of the main requests we at John Thompson receive from the market are for cogeneration, capacity upgrades and burning of problematic biomass fuels. These three requirements were used as the starting point for the development of a new retro-fit product called the Platen Evaporator.

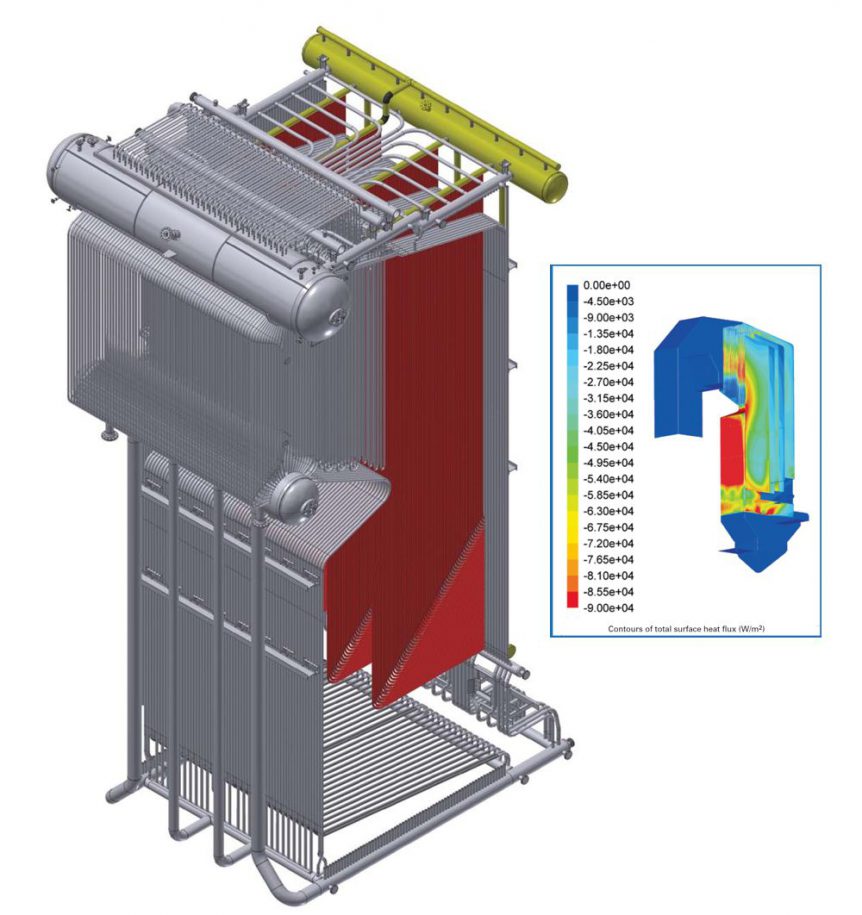

The Platen Evaporator can be seen as a boiler inside a boiler for the application of cogeneration. It is a retrofit product fitted inside an existing boiler. The boiler furnace surface area is extended by introducing vertical water walls at a very wide pitch over the width of the combustion chamber. These water walls are connected to a separate steam drum. One of the walls receives steam from the drum for superheating.

This configuration allows the designer to cater for any steam pressure independent from the existing boiler pressure. It is, therefore, ideal for cogeneration at highpressure within a low-pressure industrial boiler. The high-pressure steam is utilised in a separate range of a condensing turboalternator set for maximum cycle efficiency.

Capacity upgrades

For capacity upgrades the water walls are merely tied into the steam water circuit of the existing boiler and therefore a second steam drum is not required. The furnace surface area is thus only extended at the same operating conditions of the boiler to achieve the extra capacity.

Typically an extra 15 to 25% of the original boiler capacity is available for high-pressure steam suitable for cogeneration or extra capacity at the existing boiler steam conditions. The upgraded condition is determined on a case by case basis.

Computational Fluid Dynamics (CFD)

For both applications CFD plays a key role. CFD is the science of predicting fluid flow, heat and mass transfer, chemical reactions and related phenomena by solving the governing mathematical equations numerically. Simulations are run on a computational mesh used to discretise the equations using control volume theory.

In the furnace, the position of the flame is manipulated by introducing combustion air in different locations at different quantities, temperatures and velocities from the CFD results. High combustion intensity in the lower confines of the furnace is required to absorb the correct amount of energy in the water walls of the Platen Evaporator. The CFD model is coupled to a one-dimensional CFD network analysis code to evaluate the steam-water side.

This novel combination of CFD and systems CFD allows the designer to fine tune the natural circulation of the twophase flow mixture to prevent overheating of the tubes. CFD is also used to evaluate the components in the boiler downstream from the furnace to eliminate high velocities and related erosion due to the higher gas volume.

Problematic biomass fuels

As the demand for biomass increases, naturally industries start to pursue fuels that are more problematic to burn. Straw is a wellknown problematic fuel. It can cause a range of operational problems including combustion fluctuations, poor fuel burnout, corrosion, slagging and fouling of heat transfer surfaces.

The accumulation of deposits reduces heat transfer rates from the flue gas to the steam circuit, causing a decrease in plant efficiency, steam temperature and capacity. A 25% reduction in the heat transfer rate may occur in a few hours due to extreme deposit accumulation rates. In a case of severe slagging or fouling, unscheduled plant shutdowns are a reality.

The traditional approach to fouling fuels is to oversize the furnace to drop the combustion gas temperature below the melting point of the ash before it reaches the first heat exchanger. The Platen Evaporator can achieve this without costly furnace extensions or multiple water-cooled passes. Again CFD proved to be invaluable to design the water walls of the Platen Evaporator for fouling fuels.

The CFD code was customised by John Thompson to account for the various mechanisms of vapour and particulate deposition. The source code was originally developed at Aalborg University in Denmark and adapted by John Thompson for spreader stoker firing. From the CFD results of fouling deposition, the correct surface area of the water walls and combustion air system can be determined.

The quantity of fouling fuel that can be burnt with the Platen Evaporator fitted depend on the size of the furnace and fouling agents present in the fuel. Therefore it is also determined on a case by case basis.

In the past, boiler designers relied on empirical methods to size furnaces and mitigate combustion related problems such as fouling. With the help of advanced modelling techniques, the engineers at John Thompson are pushing the boundaries by designing heat exchangers situated in the flame to extract energy more efficiently and cost-effectively.

Platen Evaporator technology can be applied to cogeneration, capacity upgrades and burning problematic fuels. New boiler designs incorporating this technology are also more cost effective due to the reduced furnace size.

View Platen Evaporator Advert pdf